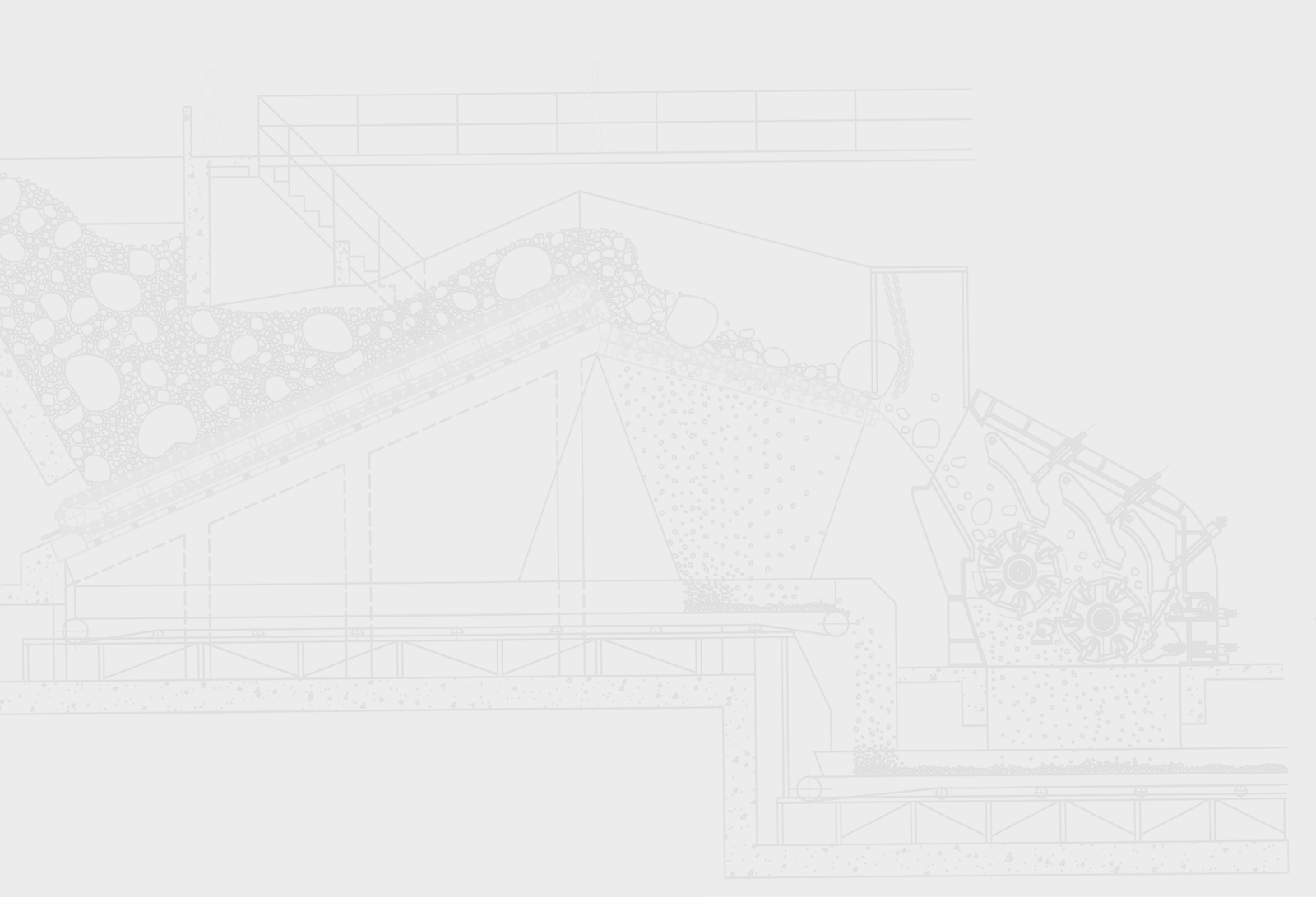

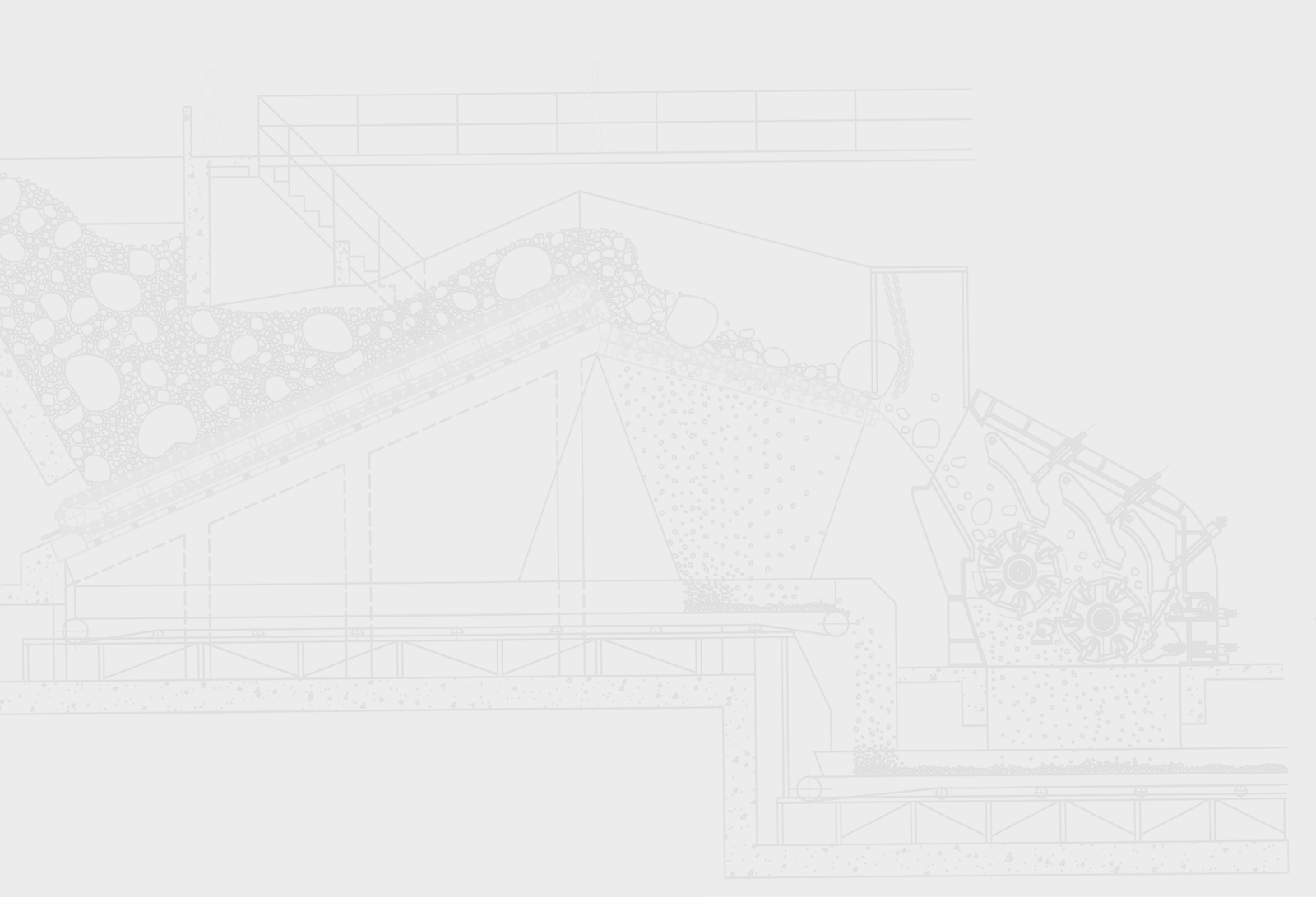

atmos is a recognized specialist for proof steel apron feeders / extractors.

Our steel apron feeders are proven effective for the extraction of difficult and clogging materials, for large lump size or high temperature materials .

The atmos apron feeders are among the most robust on the market.

They guarantee the primary stations’ supply and regulation. They are usually used to unload the hopper.

Our apron feeders range is equiped with BULL type components (chains, rollers). These will garantee almost non-existent maintenance (chains and rollers lubricated for life).

The deck is made of specific mechanically welded pans designed by atmos. Full pans recovery provides an almost perfect sealing (even on the sides).

Ease of use and reduced maintenance limit production outages thus allowing better productivity/profitability.

Our apron feeders range also includes steel apron feeders with mechanical chains composed of rods and support rollers. These apron feeders are very durable and have a small congestion for installation in various configurations.

If you are interested by our equipment, do not hesitate to contact us at contact@atmos-handling.com